Marine equipment and solutions for methanol as fuel

Fuelling a new phase in decarbonization

Methanol is the next likely step on the marine industry’s journey to a sustainable, zero-carbon future. It promises to cut CO2 output by 95%, while also reducing or eliminating other vessel emissions. If produced from renewable green sources, it can bring us to a level of carbon neutrality. However, methanol will demand new technologies and a different way of looking at the energy balance on board. Alfa Laval is at the cutting edge of methanol solutions – and is ready to partner with you in making the transition.

Methanol fuel line and combustion

Methanol is a low-flashpoint fuel that poses new demands when it comes to fuel supply and combustion. Alfa Laval solutions are at the cutting edge of these aspects.

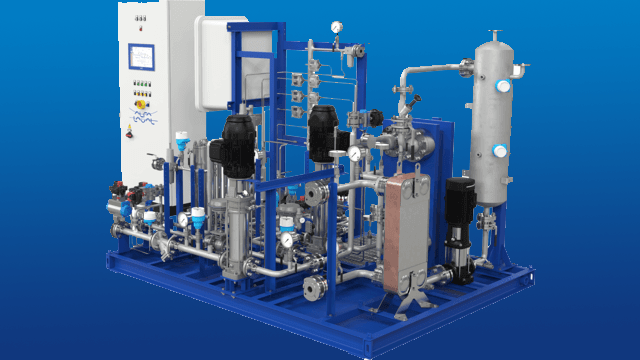

Fuel supply system

The Alfa Laval FCM Methanol is a low-flashpoint fuel supply system (LFSS) that can be adapted to any kind of marine engine and vessel design. It is a proven technology that has been operating on methanol fueled vessels sailing around the world since 2015.

Enabling the move to methanol as fuel

Find out why the Alfa Laval FCM Methanol is the leading choice of low-flashpoint fuel supply system (LFSS) in today’s methanol projects. This short video explains why more than a pump is needed, and it shows how the FCM Methanol lives up to the challenge – from flexible installation to peace of mind in operation.

Marine equipment and solutions for methanol as fuel

Built on a century of thermal expertise, Alfa Laval Aalborg boilers are prepared to run on methanol, thanks to our future-proof MultiFlame burner concept. Adding to our already extensive combustion knowledge, we are now conducting large-scale methanol testing at the Alfa Laval Test & Training Centre.

Heating and cooling

Methanol is similar to liquid fuels that are already in widespread use in the marine industry, but it has both a low flashpoint and an aggressive nature. Alfa Laval offers several heat exchanger types that can handle the temperatures, pressures and corrosion risks associated with methanol operations.

Power from waste energy

The Alfa Laval E-PowerPack uses Organic Rankine Cycle (ORC) technology to create electrical power from any heat source on board. By letting you take advantage of all available waste energy, even when steam demands are minimal, it can help you retain fuel economy despite the higher cost of methanol.

Methanol and energy demands

Besides having different properties compared to traditional fuels, methanol will change the energy dynamics on board. Alfa Laval is providing the solutions to keep the energy balance as vessels move towards greater sustainability.

Power generation

Methanol contains less energy than traditional fuels, which means additional energy will be needed. To complete the energy balance, Alfa Laval and leading partners are developing high-temperature proton exchange membrane (HTPEM) fuel cells adapted for marine use.

Waste heat recovery

The Alfa Laval Aalborg Micro exhaust gas boiler supports energy efficiency in multiple ways. Connected to a fired boiler, it supplies steam to a shared steam drum, reducing the need to use the burner. Used with the E-PowerPack and a plate heat exchanger, it delivers waterborne heat energy at a temperature that maximizes power output.

Alfa Laval Test & Training Centre

The innovation needed to work with methanol on board is well underway at the Alfa Laval Test & Training Centre. With its 2800 m2 of testing space, this unique R&D facility is providing deeper insights into methanol handling, methanol combustion and fuel cell technologies. The efforts will ensure safety and efficiency on tomorrow’s more sustainable methanol-fuelled vessels.